(January 8, 2026 · Comprehensive Industry Report)

As the new year begins, the global commercial vehicle tire industry is undergoing a profound transformation at an unprecedented pace and depth. On one front, Chinese enterprises are accelerating their global expansion, deploying manufacturing capacity and expertise to strategically critical regions. On another, driven by the sweeping electrification of commercial vehicles, tire technology itself is being fundamentally reshaped—from materials and structural design to functional performance.

Meanwhile, a series of recent truck tire fire incidents have served as a sobering reminder that regardless of how advanced technology becomes, safety remains the industry’s unshakable foundation. Innovation, globalization, and safety together form the three defining themes shaping the current evolution of the commercial vehicle tire sector.

I. Strategic Expansion Westward: A Chinese Tire Giant’s Move into Morocco Signals a New Phase of Globalization

Against the backdrop of rising headwinds to globalization, Chinese tire manufacturers are demonstrating a more strategic, proactive, and resilient approach to overseas expansion. At the start of 2026, leading domestic manufacturer Guizhou Tyre Co., Ltd. announced a major investment plan to build an intelligent manufacturing project with an annual capacity of 6 million passenger car radial tires in Morocco, North Africa.

The project carries an estimated total investment of nearly USD 300 million and will be implemented through a wholly owned local subsidiary.

This move represents far more than a simple relocation of production capacity—it is a carefully calculated strategic maneuver. Located at the northwestern tip of Africa, Morocco controls a key gateway between the Mediterranean Sea and the Atlantic Ocean and sits directly across from Europe. The country enjoys favorable free trade agreements with major economies, including the European Union and the United States.

Guizhou Tyre’s investment precisely targets these geographic and trade advantages, aiming to establish a regional manufacturing and export hub serving Europe, Africa, and North America. According to the company’s announcement, the project is intended to “enrich product structure, optimize global capacity layout, and enhance operational resilience and risk resistance.”

This development signals that leading Chinese tire manufacturers are moving beyond a model centered solely on product exports toward deeply localized operations spanning R&D, manufacturing, and sales. By building an intelligent manufacturing base in Morocco, companies can respond more rapidly to global market demand while effectively mitigating trade barriers. This marks the entry of China’s tire industry globalization into a new stage defined by regional hubs and deep-rooted international deployment.

II. Riding the Electrification Wave: Specialized Tire Technologies Address Core NEV Challenges

Running parallel to global expansion is the technological self-reinvention of tires in response to vehicle electrification. New energy commercial vehicles—especially fully electric trucks and buses—place significantly higher demands on tires than traditional internal combustion vehicles. Instant high torque and increased curb weight require tires to carry heavier loads, resist abnormal wear, and simultaneously maintain low rolling resistance to maximize driving range.

Innovation begins with market pain points. Sailun Group’s newly launched “Wear-Resistant Expert” series directly targets the core demands of new energy commercial vehicles. Featuring a high-strength dual-sidewall carcass structure, the tire significantly improves impact resistance and reduces risks such as bulging and deformation. Its unique four deep longitudinal grooves combined with fully connected transverse grooves enhance wet-road drainage and safety.

The series boasts a wear resistance index of up to 640 and has been tested to achieve an ultra-long service life of 120,000 kilometers, approximately 30% longer than comparable products—offering fleet operators a genuinely durable and reliable solution.

Similarly, for heavy electric pickups, Hankook Tire’s iON HT demonstrates a comprehensive technical response. Its “XL” extra-load design supports vehicles exceeding 3 tons in total weight. A proprietary ProDurable tread compound and optimized tread pattern evenly distribute ground contact pressure, counteracting severe tread tearing caused by instant electric motor torque. Hankook claims a tread life of up to 128,000 kilometers.

Additionally, rolling resistance is reduced through Roll Lite compound technology and optimized curing processes, while specialized sound-absorbing layers help suppress road noise—one of the most noticeable characteristics of electric vehicles. Together, these innovations illustrate the delicate engineering balance required of EV-specific tires, where durability, efficiency, comfort, and safety must coexist.

III. Precision Innovation: Scenario-Specific Tire Solutions for Modern Logistics

Innovation in the tire industry is not limited to powertrain changes—it is increasingly driven by specific operational scenarios. In advanced logistics markets such as Japan, four-axle low-floor trucks are widely used to improve transport efficiency. Due to their unique configuration, tires on the second front axle are subjected to sustained lateral forces, leading to severe shoulder wear and significantly higher maintenance costs.

To address this precise issue, Toyo Tires collaborated with major Japanese logistics operator Fuji Transport to co-develop and launch the M630 all-season tire. A newly designed tread pattern with a wider shoulder area and increased tread width effectively suppresses block deformation.

According to official data, shoulder wear is reduced by an impressive 61% compared to the previous generation, while overall tire life is extended by approximately 5%. Through optimized center block design and the application of e-balance technology, the tire also achieves an approximate 6% reduction in rolling resistance, improving both energy efficiency and durability.

This model of deep co-creation between manufacturers and end users, focused on solving specific real-world operational challenges, reflects a broader trend toward scenario-based, customized tire development.

IV. Intelligent Evolution: From Passive Components to Data-Driven Safety Interfaces

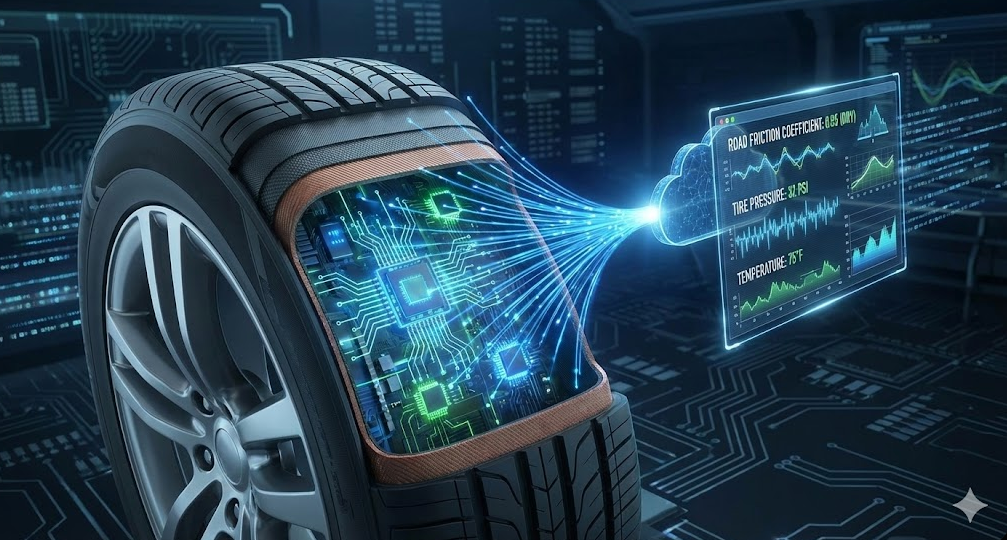

While electrification redefines tire physical performance, intelligence is reshaping the tire’s role and value. Industry leaders are transforming tires from silent consumables into smart safety components capable of sensing, communicating, and supporting decision-making.

Pirelli’s Cyber™ Tire System exemplifies this direction. According to company executives, the system is fundamentally an algorithm-driven intelligent decision platform. Embedded sensors enable real-time monitoring of road conditions (dry, wet, snow-covered), tire status (pressure, temperature, wear), and vehicle dynamics.

This data can provide immediate safety alerts to drivers and, in the future, integrate deeply with ADAS and autonomous driving systems, supplying critical input for suspension tuning, torque distribution, and braking response—thereby proactively enhancing safety and efficiency.

In China—the world’s largest and most receptive market for intelligent electric vehicles—the localization of tire intelligence is accelerating. Companies such as Pirelli have activated driving simulators at their Chinese R&D centers, using AI algorithms to process massive datasets and rapidly respond to local automaker customization needs. This signals a future in which tires are no longer isolated components, but essential data nodes within the intelligent connected vehicle ecosystem.

V. Safety Alarms Sound: Extreme Incidents Reinforce the Need for Fundamental Maintenance

Despite advances in intelligence and technology, tire safety ultimately depends on meticulous inspection and maintenance. At the beginning of 2026, two serious truck tire fire incidents in Xinjiang and Jiangsu Province served as stark warnings.

On January 3, along Provincial Highway 301 in Xinjiang’s Gobi Desert, a semi-trailer truck caught fire at the wheel after prolonged driving caused overheated brake pads and wheel hubs, igniting the tire. Thanks to the quick response of nearby construction personnel using onboard fire extinguishers and hoses, a cargo of white sugar valued at over 300,000 yuan was saved.

In a separate incident on February 8 at a service area along Changzhou’s West Ring Expressway, a truck loaded with wheat bran suffered a left rear tire blowout that immediately ignited, producing visible sparks. Disaster was averted only through the combined efforts of service area staff and firefighters.

Both cases reflect a common root cause: heat accumulation from long-distance, high-load driving. Rescue professionals emphasized afterward that during extended journeys—especially after long downhill sections—drivers must regularly inspect brake systems and tires. High-temperature brake drums should never be doused with water; vehicles should instead be parked safely and allowed to cool naturally.

Abnormal tire pressure, aging rubber, and accumulated structural damage can all become triggers for blowouts or fires at highway speeds. These incidents underscore the critical importance of making systematic pre-trip and post-trip inspections—particularly of tires and braking systems—an unskippable safety protocol, especially ahead of peak transport periods such as the Spring Festival travel season.

Conclusion

In 2026, the commercial vehicle tire industry stands at the intersection of multiple transformative forces. Chinese manufacturers are executing increasingly mature and precise globalization strategies, strengthening supply chain resilience through overseas intelligent manufacturing bases. Technological innovation continues to push boundaries with electrification-focused and scenario-specific products. Intelligence is injecting new vitality into tires, transforming them into active participants in future smart transportation systems.

Yet amid all these changes, one mission remains constant: safety. Only by uniting cutting-edge innovation with rigorous, fundamental maintenance practices can the industry move forward with confidence—and ensure its wheels roll steadily on the road of transformation.

Copyright © 2024-2025 Firemax Sdn. Bhd Company. All rights reserved.

Headquarters address:303 block C, Pusat Dagangan Phileo Damansara 1, No 9 Jln 16/11 Off Jalan Damansara, 46350 Petaling Jaya, Selangor. Malaysia Sales Hotline:+60 11-6449 0688 After-sales hotline:+60 11-6449 0688